Diamond Manufacturing is your One-Stop,

Premier Perf Provider

for Perforating, Leveling, Fabricating, Custom Engineering, Product Assembly, Inventory & Program Management, and Expert Material Handling. We make, monitor, and maintain all of our tooling on site to achieve unparalleled precision, quality, and innovation.

Backed by

the Best

In October 2010, Diamond Manufacturing became a wholly owned subsidiary of Reliance, Inc. By leveraging the relationship with Reliance, Diamond is strategically positioned to benefit from preferred availability and pricing of supply chain materials and investment in capital equipment to continue to exceed customer service expectations.

All in

the Family

Diamond is a family of six facilities strategically located in the United States. Five of those are full-service perforating, fabricating and finishing facilities doing business as Diamond Manufacturing, Ferguson Perforating and McKey Perforating. We also operate a fully stocked inventory and quick-ship facility, Perforated Metals Plus. All Diamond locations are located within a short distance of major East Coast and midwestern markets.

Fully

Equipped

Whether your job requires the raw power of a 500-ton perforating press or the intricate precision handling of a fiber laser, Diamond has you covered from the start of your project to the finished product for perforating, leveling, fabricating, finishing and program management. Boasting the largest consolidated array of perforating presses in North America, Diamond has you covered for your next job.

Perforating Capabilities

With 56 perforating presses in operation across the United States ranging in capacities from 20 to 500 tons, processing material widths up to 84" and thicknesses up to half an inch, Diamond's perforating capabilities are unmatched in the industry. We perforate up to 100 million lbs. of steel per year and are equipped to handle the most delicate of alloys and the hardest stainless steels.

Fabricating Capabilities

Let Diamond produce your assembly-ready finished product leveraging our full-service fabrication lines. Whether you are looking for value-added post-perforating fabrication or straight fabrication for non-perforated items, Diamond has you covered. Our expert fab team operates an extensive arsenal of equipment including Fiber and CO2 lasers, CNC and turret presses, brake presses, stamping and blanking presses, and shears. We also provide degreasing, welding, timesaving, powder coating and other finishing services.

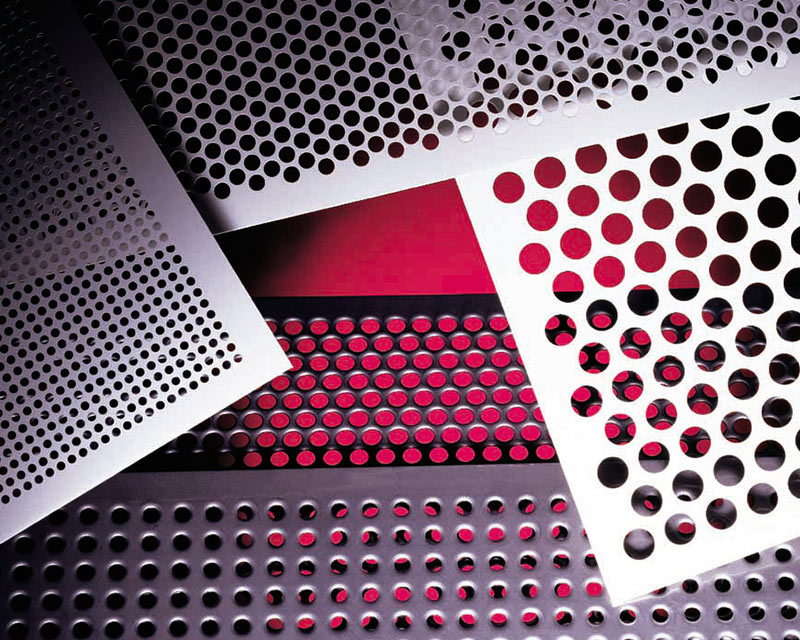

Materials & Patterns

Diamond perforates a wide variety of materials including carbon steel, aluminum, stainless steel, other alloys and plastics. We are capable of perforating either coils up to 60" or standard sized sheets. Whether your material is in stock, you need a custom order, or you're looking for labor-only toll work, you can count on Diamond Manufacturing to process your material accurately and on time.

To satisfy the varying needs of our customers, Diamond invests in tooling and machinery that can perforate more than 4,000 patterns, produce material in tolerances tighter than industry standards, and offer it as sheet, coil, tube, fabricated, or finished product.

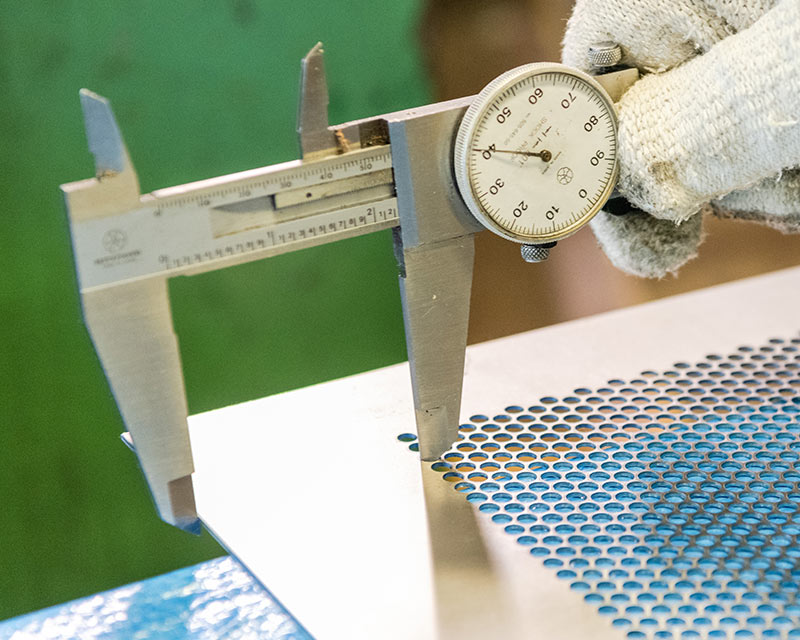

Diamond Manufacturing has a proven record of supplying products that have a 99.77% acceptance rating. Adhering to strict internal audits, we offer tolerances and specifications that surpass industry guidelines and we continue to improve our processes each day to meet the highest quality standards.

Diamond Manufacturing by the Numbers

year founded

tons of steel perforated per month

perforating presses in operation

perforated patterns in stock

Diamond Manufacturing is a wholly owned subsidiary of Reliance, Inc.

Site designed and developed by Blair Inc.

Contact Us

Physical address:

243 West Eighth Street

Wyoming, PA 18644

Mailing address:

P.O. Box 4174

Wyoming, PA 18644

© 2023 Diamond Manufacturing Company

Site designed and developed by Blair Inc.